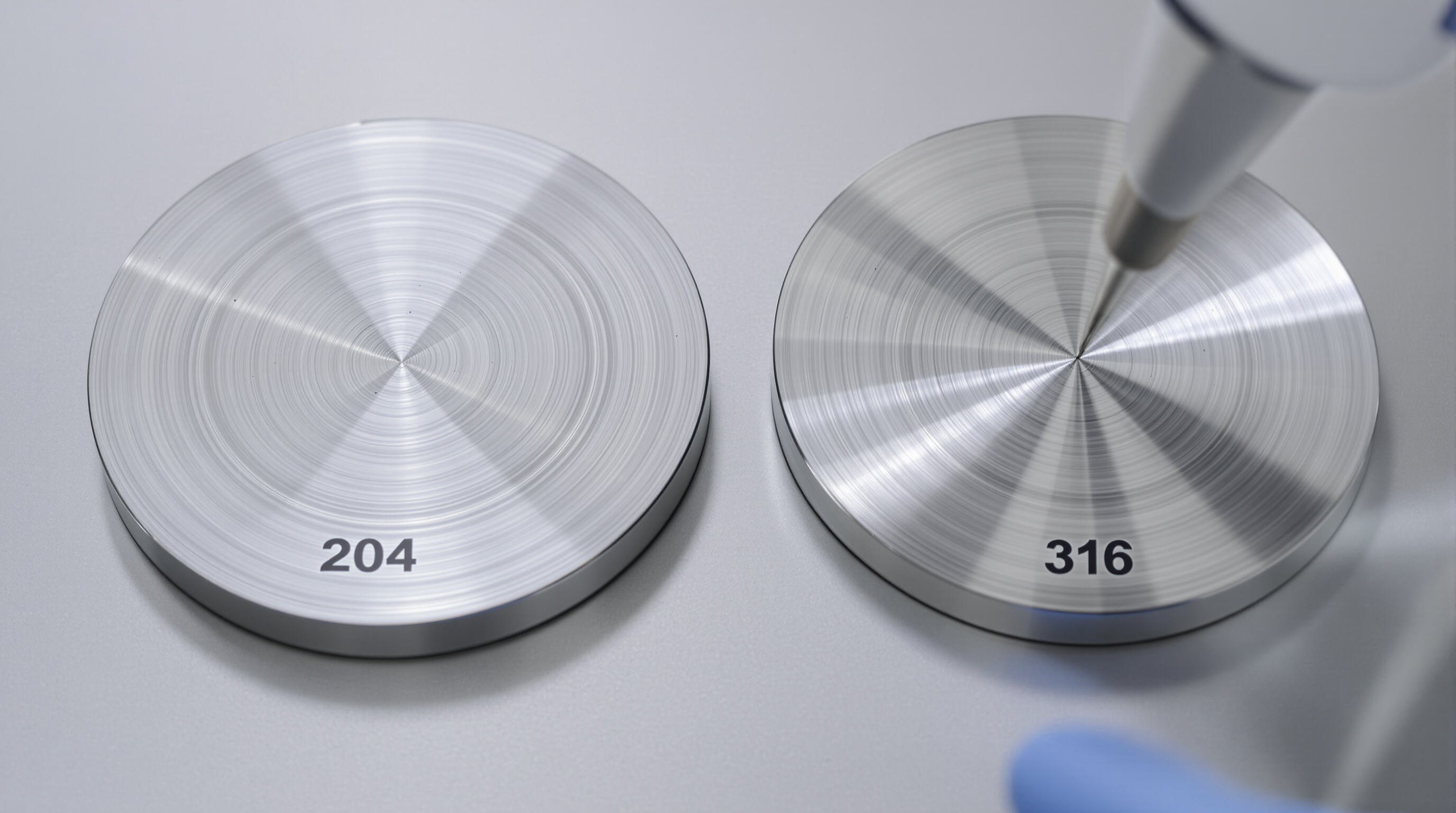

የ304 እና 316 የማይዝመው ብርንቆም ኬሚካላዊ ውህደት እና መሰረታዊ ልዩነቶች

ዋና ዋና አካላት: ክሮሚየም፣ ኒኬል፣ እና ሞሊብዶነም በ 304 እና 316 ውስጥ

የ304 እና 316 የማይዝን ብርጭቆች መካከል ያለው ዋና ልዩነት በእነሱ ባህሪያዊ አካባቢያት ላይ ይመስላል። ሁለቱም አሉይስቶች ለኦክስጅን ተቃውሞ እና ለዲቪዥን አቅም ለክሮሚየም (16.5–19.5%) እና ለኒኬል (8–13%) ይጠቀማሉ፣ ግን 316 የሚያካትትው 2–3% ሞሊብዲነም በጭንቅላት የሚያሳየው በጣም ጥሩ አፈፃፀም ነው።

| ኤለመንት | 304 የማይዝመው ብርንቆም (%) | 316 የማይዝመው ብርንቆም (%) |

|---|---|---|

| ክሮሚየም | 18.0 – 19.5 | 16.5 – 18.5 |

| ኒኬል | 8.0 – 10.5 | 10.0 – 13.0 |

| ሞሊብዲናም | – | 2.0 – 2.5 |

ሞሊብዲናም የያዘው ቁሳቁስ 316 የመጥፋትን እና ለ cracks መ fissure መቸግር ያሻሽላል፣ ይህም በተለያዩ አካባቢዎች የሚንቀሳቀሱ ታንከር ተርክ ለምሳሌ በክሎራይድ የተሞላ የባህር አካባቢዎች ላይ ተስማሚ ያደርገዋል።

ሞሊብዲናም በ 316 የማይዘግ ብረት ውስጥ የመበላሸት መቸግር እንዴት እንደሚያሻሽል

ሞሊብዲናም በ 316 የማይዘግ ብረት ውስጥ ከተጨመረ የኦክሳይድ ሐማ አብሮ የበለጠ ጠንካራ ይሆናል፣ ይህም በክሎራይድ መጥፋት እና በአሲድ ጉዳት ተቃርኖ በመሬት ላይ የሚገኝ አይነት እንደ ማይክሮስታንዳርድ ቁሳቁስ እንደሚያገልብጥ ያረጋግጣል። የምርመራ ውጫዊ ውጭው የሚያሳየው እነዚህ ሞሊብዲናም የተጠናቀቁ ቅይጥ ቁሳቁስ በተለያዩ ሁኔታዎች ላይ በመሬት ላይ የሚገኝ የማይዘግ ብረት ከዚያ ሲነፃፀር በግምት 40 በመቶ የመበላሸት ችግሮችን ሊቀንስ ይችላል። በባህር አካባቢ ወይም በከባድ ኢንዱስትሪ ውስጥ የሚያጓዙ የጠንካራ ኬሚካሎች ታንከር ተርክ ሲሆን አምራቾቹ በግምት 15 እስከ 20 የተጨማሪ ወር ድረስ የመቆየት ጊዜ እንደሚኖራቸው ይገነዘባሉ በዚያ ጊዜ ላይ የመበላሸት ጉዳት ምክንያት የመዋቅር ችግሮች ሊኖሩ ይችላሉ።

በተለያዩ ትውልድ ማመንያ ውስጥ የመበየድ ተቋቋም: 316 የነዳጅ መኪና ጥቅሞች

በባህርና በባህር ጊዜ የሚሰራው የ316 የማይዘገይ ብረት የክሎራይድ ተቋቋም

የስቴይንሌስ ብርዝግ ደረጃ 316 በተፈጥሮ የሚፈጥር የኦክሳይድ ፍልም ምክንያት በከባድ ማው ላይ በጣም ጥሩ አፈፃፀም ያሳያል፣ ምክንያቱም የውስጡ አካል አካል የሞሊብዲኑም እስከ 2 እስከ 3 በመቶ ይዟል። የመደበኛ 304 የስቴይንሌስ ብርዝግ ብቻ የክሮሚየም እና የኒኬል አካል አለው፣ በመሆኑ የተፈፃፁ የአንዳንድ ማጥፋት የክሎራይድ ተብሎ የሚታወቁ ችግሮችን በከፍተኛ ማው ያካትታል። የመንገድ መሣሪያዎች በአገሪቱ የታችኛው ክፍል የሚሰራውን የአካባቢ ጥናት ከወቅቱ በፊት በማቴሪያል ዒድገት መፃሕፍት የተለቀቀው የአንዳንድ ማጥፋት በሁለት ሶስተኛው ይቀንሳል። ይህ የሚፈፅመው በተፈጥሮ የሚፈጥር የኦክሳይድ ፍልም ምክንያት ነው፣ ይህ አካል በጣም ጥሩ አፈፃፀም ያሳያል በከባድ ማው ላይ፣ በተደጋጋሚ የሚነሳው የሞሌ ማው፣ በተደጋጋሚ የሚታየው የባህር ማው፣ እና በተደጋጋሚ የሚታየው የመንገድ ማው ለመቀየር የሚያገለግል የሰውነት አካል ነው። ለዚህ ነው የተለያዩ የታንከር ተራስ አምራቾች የደረጃ 316 ብርዝግ የሚያገለግሉ በባህር አጂ እና በመገናኛ ቦታዎች ላይ የሚሰሩ ተራሶች ላይ የሚያገለግሉት ለዚህ ነው።

የደረጃ 316 የታንከር ተራሶች አፈፃፀም በኬሚካላዊ ሂደቶች እና በከባድ ማው ያላቸው ቦታዎች ላይ

በኬሚካላዊ ማስተላለፍ ውስጥ፣ 316 የማይዝመው ብረት ይሰጣል በመቶኛ በላይ የተሻለ ተቃዬ ወደ ሰልፌሪክ አሲድ እና ብራይን የመጨመር ቅዝቃዜ 50,000 ፒፒኤም የሚያሳየው 304 የሚያሳየው ከዚያ ነው። ሲሆን 304 የታንከር መኪናዎች በጠንካራ ቦታዎች ውስጥ በአራት ሳጥን ወይም 12 ወር ውስጥ የበለጭ ጉዳት እንደሚያሳዩ እናውቃለን፣ የ316 አሃዞች ደግሞ የሊነር መተካት ያስፈልገዋል እስኪያደርስ በ5-7 ዓመታት ውስጥ የማይበ leak ጥራት ይጠብቁታል። ይህ የማይበላሽ ቁሳቁስ ለመከ끌 አስፈላጊ ነው:

- ኢንዱስትሪያል የማጽዳት አgentታዎች

- ፔትሮኬሚካል በማኅበረሰብ ውጤቶች

- የበለጠ አካላዊ ቁሳቁሶች ያላቸው የመሰረብ ፍሉዎች

የጉዳይ ትንታኔ፡ የ316 የማይዝመው ብረት የታንከር መኪናዎች የመቆየት ህልውና በከፋ ማስተላለፍ ላይ

የ10 ዓመት ጉልፍ የመሬት መስመር ላይ የተካሄደ ሙከራ 316 የማይዝመው ብረት የታንከር መኪናዎች የሚያስፈልጉትን 47% ያነሰ የመገንጠል ግንኙነቶች ከ304 የሚያሳዩ ሞዴሎች በላይ። የቁጥጥር ውሃ ጥቁር ምንጭ ቢኖርም፣ 316 የመተላለፍ መኪናዎች የተሻለ አፈፃፀም አሳዩ፡

| ሜትሪክ | 316 ግንባታ | 304 ግንባታ |

|---|---|---|

| አማካይ አገልግሎት ዕድሜ | 18 አመታት | 12 አመታት |

| የዝገት ጋር የተያያዕ ጥራት ማስተካከያ | 0.2/ዓመት | 1.7/ዓመት |

| የቀራሪ ድፍን ጠንካራ ክፍል | 94% የተቆጠበ | 78% የተቆጠበ |

እነዚህ ውጤቶች 316 በመጀመሪያ ላይ የላቀ ዋጋ እንዳለው እና በተጠቃሚ መሬቶች ውስጥ የተጠበቀው ጥራት ተስማሚነት እና የደንበኛ ገዢ ግዴታ ላይ በቀጥታ የሚነኩር እንደሆነ ያረጋግጣሉ።

304 የማይዝበው ብረት በርበሪ መኪናዎች: በዝቅተኛ ሙቀት ሁኔታዎች ውስጥ የበቀላ የሆነ ጥረት

304 ለባህር ባህር ለመጓጓዝ አስቸጋሪ መተግበሪያዎች: ምግብ ደረጃ እና በዝቅተኛ ክሎራይድ የሚታወቁ የኢንዱስትሪ ማስተላለፊያ

304 የማይዝበው ብረት ለጠንካራ እና በዝቅተኛ ደረጃ የሚዝበው ሁኔታዎች ለመጠበቅ ተስማሚ ነው። 18% ክሮሚየም እና 8% ኒኬል ጋር እንደ ምግብ ደረጃ እና የፋርማሲውቲካል ማስተላለፊያ ለመጠበቅ ለመጠበቅ የተረጋጉ የዝነብ ተቋም ይሰጣል። የምግብ ምርት መሳሪያዎች ውስጥ 70% በላይ 304 ይጠቀማል ምክንያቱም FDA ጋር የተዛመደ መሆኑ እና ለማጽዳት ቀላልነቱ ምንም እንኳን የሚከተሉትን ይכלול:

- ዳይሪ እና ማጣቀሻ ማስተላለፊያ

- የተረኛ ዘይት ማጠራቀሚያ

- በውስጥ ክልሎች ውስጥ የማይዝበው ኬሚካል መድረሻ

በከፍተኛ ክሎራይድ ሁኔታዎች ውስጥ የአፈፃፀም ችሎታው ይቀንሳል ግን በዝቅተኛ ሙቀት ሁኔታዎች ውስጥ የገንዘብ ችሎታ ላይ የተመተዘ አሟላቶች ለ304 የተረጋጉ እና የተወዳዳሪ የሆነ የመርሃ ጥረት እንደሚቀጥል ያሳያል።

በማይነፃፀር እና የውስጥ ክፍሎች ላይ የ304 የማይዘገይ ብረት ጥቅሞች

316 ወደ 304 የመቀየር የመጀመሪያ ዋጋን 20–30% ያቀንሳል እና በዝቅተኛ ኮርሮዥን ክልሎች ውስጥ የተገኘ አፈፃፀምን ያቆያል። የውስጥ ክፍል አሟላቶች ይጠቀማሉ:

- በጣም ዝቅተኛ የፒቲንግ አደጋ ምክንያት ዝቅተኛ ጥበቃ

- የቅድሚያ ማረጋገጫ እና የሻር ጥራት ተሻሽሎ

- የመደበኛ ጭነቶች ለ (515 MPa የመታጠፍ ጥንካሬ) በቂ የሜካኒካል ጥንካሬ

ለማይነፃፀር መንገዶች እና በቆጣቢ ኮርሮዥን ኤክስፖዙር ጋር የተገኙ ተቋማት ለ304 የሚያስተዋውቅ የተመጣጠነ ጥምር ይሰጣል በሞሊብዲነም የተሻሻለ አካላት ያለ መሆኑን ያረጋግጣል።

የሜካኒካል ጥንካሬ እና የረጅም ጊዜ የመቆየት ችሎታ: 304 እና 316 የማይዘገይ ብረት

የመታጠፍ ጥንካሬ፣ የአፀፋ ተቃዣ፣ እና የዋና መዋቅር አፈፃፀም በከባድ ጭነቶች ምክንያት

የ316 የማይዘገይ ብረት የላቀ የሜካኒካል ጥንካሬ ይሰጣል፣ ሲዘገይ በሞሊብዲነም የመታጠፍ ጥንካሬን በ15–20% እና በላይ ይጨምራል ለ304 የተነፃፈው። ይህ ለከባድ ማስተላለፊያ እና ለከባድ የሙቀት ለውጦች ተስማሚ የሆነውን 316 ያደርጋል። ዋና ልዩነቶች ይጨምራሉ:

| ባህሪ | 304 የስቴንለስ ስቲል | የ316 የማይዘገይ ብረት |

|---|---|---|

| የመራጭ ጠንካራነት (ኤምፒኤ) | 515–720 | 515–795 |

| የመታየት ጠንካራነት (ኤምፒኤ) | 205–310 | 240–315 |

| በመቆራረጥ ላይ የመራጭነት (%) | 40–60 | 35–50 |

ខሶ 304 ለጭንቅላት መከላከያ ከፍተኛ የመራጭነት ያቀርባል፣ 316 የላቀ ጠንካራነት (70–90 HRB እና 60–80 HRB) ስላለው የተደጋጋ ጭነቱ ወቅት የመታጠቢያ እና የመዋቅር ጭንቀትን በተሻለ መልክ ይከላከላል።

በረጅም ጊዜ ውስጥ የመቆየት ችሎታ ዝንባሌዎች፡ የመቆጣጠሪያ እና የብሬክ ቅርጽ 304 እና 316 በተሽከርካሪዎች ውስጥ

የታንከር ላይ የተሰሩ ፈተናዎች የጠንካራ ብረት ደረጃ 316 የመጨረሻው የድራይን ግድግዳ ጥልቀት በአስር ዓመታት የቀጣይነት የibr vibration ጭንቀት ተጭኖ ቢያንስ 94 እስከ 97 ቢመቶ ይቆያል እንዳረጋገጧል፡፡ ይህ በተመሳሳይ ሁኔታዎች ምክንያታዊ 304 የጠንካራ ብረት ብቻ ሲሆን የመጨረሻው የድራይን ጥልቀት በ88 እስከ 91 ቢመቶ ብቻ የሚቆይበትን ከማየታችን በላይ በጣም ውጤታማ ነው፡፡ 316 ን የሚለዩት በመገጣጠሚያ ነጥቦች ላይ የሚያሳይበት የጭንቀት ምላሽ ነው፡፡ ምክንያቱም ሲጠቀሙ ሲበዛ ይስራል፣ ስ Crack cracks በዚያ ነጥብ ላይ በጣም ቀስ ቀስ ይተላለፋሉ - በተለዋዋጭ የተጓዳኝነት መጠን ላይ በ30 እስከ 40 ቢመቶ ድረስ የቀነሰ፡፡ አሁን፣ የመጥፋት ችግር የሚታየበት ቦታዎች ላይ 304 በተደጋጋሚ ማረጋገጫ የሚያስፈልገው (በ18 እስከ 22 ቢመቶ ድረስ የበለጠ ፈተናዎች የሚያስፈልጉት) ከሆነም፣ በርካታ ኩባንያዎች ግን ዋጋው ልዩነት በጣም ትልቅ ስለሆነ እንደገና ይሄውን ይመርጣሉ፡፡ የባህር ክፍሎች እና የኬሚካል ሂደት ፋብሪካዎች ከጠፋ ውጭ የሚሰሩ ሰዎች ለሸለቆች እና አሲዶች ተጋራራቢ የሆነ ቦታዎች ላይ የሚሰሩ ለዚህ ዓይነት ሁኔታዎች የሚያስፈልጉ በቀጥታ የመቆያ ጥናት ቢያስፈልጉም፣ 304 ደግሞ በጥራት የተጠበቀ የመረጃ ጥረዛ ነው፡፡

በ 304 እና 316 ታንከር ተርክ መካከል ከአሠራር ዓላማዎችዎ መሰረት መረጃ መምረጥ እንዴት

የመጠን ቁሳቁስ ከአካባቢው ጋር መዛመድ: 316 ታንከር ተርክ ላይ ማስተዋወድ ጊዜ መቻለ ነበር ግን?

316 እንደ ብረት የተሰራ ታንከር ተርክ በተለይ በተደበቀ ዓይነት ውስጥ ሲታይ ይለያያል። ይህ ቁሳቁስ የሚገንዘብ በግ около 2 እስከ 3 በመቶ መጠን የሞሊብዲነም ክፍንት ይኖረዋል፣ ይህም የክሎራይድ ጉዳት ከማይፈታ ቁሳቁስ ጋር ሲነፃፀር ተጨማሪ የጢበብ አገልግሎት ይሰጣታል። ይህ የታችኛው የባህር አቅጣጫ ክልሎች፣ የኬሚካል ፋብሪካዎች፣ ወይም በአደገኛው የመንገድ ማነፃፀሪያ በጭነት የተሞላበት የረራ ወቅት ለስራ ሲያገለግል ይህን ዓይነት ታንከር ተርክ ለመጠቀም ተገቢ ይሆናል። ፕኔማን ከ2023 የተሰጠው የምርመራ ውጫው እንደሚያሳየው፣ የታችኛው የባህር አቅጣጫ ክልሎች ላይ የሚሰሩ ብስክሌቶች ከመደበኛው 304 ምርጫዎች ወደ ጠንካራው 316 ምርጫዎች ሲተዉ 23 በመቶ የተቀነሰ መተካት ዕድገት እንደተገኙ አሳይቷል። ለአካባቢዎች የሚያገለግሉ የአሲድ አካላት፣ በተደጋጋሚ የባህር ውሃ ጣይቻ፣ ወይም የመንገድ ማነፃፀሪያ የሚቆይበት አካባቢዎች ላይ የሚሰሩ ኢድገቶች ለመጀመሪያው ብትናነቅ ቢቀርብ እንኳን 316 ለመግዛት የተደረገው ገንዘብ በረጅም ጊዜ ውስጥ በጣም ጥሩ ትርፍ ይሰጣል፣ ምክንያቱም ይህ ታንከር ተርክ ረጅም ዕድሜ ይኖረዋል እና በተደጋጋሚ አይገድላም።

የበድር ተጠቃሚ ትንተና: 304 እና 316 የማይዝጉ ብርጭቆች የጠቅላላ አገልግሎት ዋጋ

ខል ቢሆን 316 ዋጋው 20-30% ከፍተኛ ነው ፣ ግን የመቆጣጠሪያው ጥንካሬ የመጠን ዋጋን ይቀንሳል። የ10 ዓመት ሲፋ፡፡

| የወጪ ምክንያት | 304 የማይዝጊ | 316 የማይዝጊ |

|---|---|---|

| የዓመቱ ጠብታ | $8,400 | $5,200 |

| የመኪና ቡድን የማትሄድበት ጊዜ | 14 | 7 |

| የመድጋገም ተደርጎ ጊዜ | እያንዳንዱ 4 ዓመት | የአስር ዓመታት ሁሉ |

እነዚህ የገንዘብ ትንሽነት በጭነት የተሸፈነበት ጊዜ የመጀመሪያ የኢንቨስትመንት ቅርብ ነው። ደግሞ ዝቅተኛ የክሎራይድ ኤክስፖዚር ጋር የሚሸጋገር ወይም ዝግጅት ለመላክ ከታወቀው 304 በጣም ትንሽ ዋጋ ያለው እርምጃ ነው።

የክልል አካባቢ አቀማመጥ: የአየር ሁኔታ፣ መንገድ ሁኔታ፣ እና የማስረጃ ጉዳዮች

በረዶች ክልሎች ውስጥ የሚሰሩ ተራንስፖርቶች የመንገድ ምድር በከፋ መጠን በጭራ ወቅት የሚያገለግሉበት፣ የስቴይንሌስ ብርት ዝገት 316 እንዲያገለግል እንዴት የበለጠ ተስማሚ መሆኑን ያስተማርታል፣ ምክንያቱም ከዚያ በጣም የበለጠ ጠንካራ ነው። ከዚህ በተቃራኒ፣ አንድ ሰው የሚያንቀሳቀስው ወይም የሚያስተላልፍው የማይበላሽ እቃ ከሆነ፣ ብዙውን ጊዜ የተለመደው 304 በጣም ጥሩ ውጤት ይሰጣል። ለምሳሌ ፍሎሪዳን አስቡት- እነዚህ አስፈላጊ መስፈርቶች የባህር ጓን በጭ proximity ውስጥ የሚሰሩ የደangerስ ኬሚካሎች ተረኛ ተራንስፖርቶች ሁልጊዜም 316 ጋር መሆን አለባቸው። የተለያዩ ክልሎች የተለያዩ መስፈርቶች አሏቸው ይሁን አንድ ነገር ላይ ብቻ ይደርጋሉ። በአሁኑ ጊዜ በአራት አቅጣጫዎች ውስጥ በአዲስ ASTM መደበኛነቶች መሰረት ለተወሰኑ የኬሚካል ማስተላለፊያ አይነቶች የሚያገለግሉትን የስቴይንሌስ ብርት ዝርዝሮች መቀየር አለባቸው። በእያንዳንዱ ክልል ውስጥ ምን ያህል የተገለጸ እንደሆነ ለመወሰን ቀድሞ ስለመግዛት ምርጫዎች መወሰን አስፈላጊ ነው።

ተደጋጋሚ ጥያቄዎች

304 እና 316 የስቴይንሌስ ብርት መካከል ያለው ዋናው ልዩነት ምንድነው?

የዋናው ልዩነት በኬሚካዊ ውስነት ላይ ይናገዘታል፤ 316 የማይዝጋ ብርቱዋን ሞሊብዲናም ይዟል፣ ይህም የ 304 የማይዝጋ ብርቱዋን ጋር ሲነፃፀር የመውረድ ችሎታን ይሻሻላ።

ለምን ነው የ 316 የማይዝጋ ብርቱዋን ለባህር ላይ የሚንቀሳቀስ ተርባሪ መኪናዎች ተስፋ ይደረጋል?

የ 316 የማይዝጋ ብርቱዋን የተሻለ የክሎራይድ ተቋም ስላለው ተስፋ ይደረጋል፣ ይህም ለባህር የሚያገባውን የአካባቢ ሁኔታዎች ለመቋቋም እንደገና ይገባል።

የትኛው የአካባቢ ሁኔታዎች ለ 304 የማይዝጋ ብርቱዋን ተርባሪ መኪናዎች ተስፋ ይደረጋል?

የ 304 የማይዝጋ ብርቱዋን ለምግብ ደረጃ እና ዝቅተኛ የመውረድ ሁኔታዎች ለምሳሌ የውስጥ መንገዶች ላይ የሚገቡ እና ዝቅተኛ የክሎራይድ ቅርበት ያላቸው ሁኔታዎች ለመቋቋም ተስፋ ይደረጋል።

የ 316 የማይዝጋ ብርቱዋን የመስተጋብር ወጪ ላይ እንዴት ይነኩራል?

ទንሽ ጊዜ ላይ የበለጠ ዋጋ ቢኖረውም፣ የ 316 የማይዝጋ ብርቱዋን የመስተጋብር ወጪ እና የማይሰራበትን ጊዜ ይቀንሳል ምክንያቱም የተለያዩ አከባቢዎች ላይ የመቆየት ችሎታ አለው።

መስፈርቶችን ማክበር መርጠኝን በ 304 እና 316 የማይዝጋ ብርቱዋን መካከል መምረጫዬን መነሳት ይገባኛል?

አዎ፣ ክልል መስፈርቶች የተወሰኑ የማይዝጋ ብርቱዋን ደረጃዎችን ለተወሰኑ የመላካት ሁኔታዎች ይጠይቃሉ፣ በተለይም ባህር ወይም የኢንዱስትሪ ክልሎች ቅርብ ሲሆኑ።