The Evolution and Global Impact of Tank Containers in Liquid and Gas Logistics

Shifting Dynamics in International Bulk Liquid and Gas Transportation

Around the world, the way we move liquid goods has changed dramatically over recent years. Instead of relying on old fashioned pipelines, most businesses now use specialized tank containers for transportation. About 58 percent of all non-petroleum liquids are actually being shipped this way these days, according to World Bank data from 2023. The real turning point came back in the 1980s when international standards were finally set for these containers, making it possible to transfer products smoothly between different modes of transport without having to constantly load and unload. A recent study by UNCTAD found something pretty impressive too. Companies that made the switch to tank containers saw their shipping expenses drop by nearly a third for those long haul chemical transports across continents. Makes sense really, since handling becomes so much simpler with standardized equipment.

Core Functions and Advantages of ISO Tank Containers in Supply Chains

Modern ISO-certified tank containers offer four key advantages:

- Multi-modal flexibility - 72-hour turnaround between transport modes vs. 12 days for traditional tankers

- Safety compliance - Built-in pressure relief valves and secondary containment systems meeting IMO/ADR regulations

- Inventory optimization - 26,000-liter capacity units serving as mobile storage during supply chain disruptions

- Environmental protection - 99.98% leak-proof performance in 2023 safety audits

These features make tank containers a resilient solution for complex logistics environments.

Market Growth: Rising Demand for Tank Containers in Chemical and Hazardous Material Transport

Hazardous materials take up about two thirds of the tank container market right now, mainly because chemical production across Asia Pacific has exploded to around 740 billion dollars according to Ponemon's latest report from last year. Looking ahead, experts are seeing some pretty strong growth numbers too. The food grade and pharmaceutical segments should grow at roughly 8.2 percent per year until 2030, while those special temperature controlled units might actually pick up even faster, maybe hitting double digits with around 14% annual increase. Over in North America and Europe combined, nearly half of all the smart containers getting upgraded these days come equipped with IoT monitoring systems. Makes sense really when we look at how much stricter safety rules have become worldwide lately.

Types, ISO Standards, and Industry-Specific Applications of Tank Containers

Understanding ISO Certification and Safety Standards for Tank Containers

Getting ISO certified means tank containers actually live up to strict standards needed for moving goods around the world. The main ones are ISO 1496 which deals with pressure tests and ISO 3874 covering how cargo should be secured inside. Most manufacturers follow these rules too – around 98% did so back in 2023 according to the International Maritime Organization. What do these standards really mean? They require materials that resist corrosion, proper pressure relief mechanisms, and regular checks on structural strength. This makes sense when we look at numbers from the Maritime Safety Report in 2022 showing certified tanks leak about 62% less than those without certification. Makes a big difference in preventing spills during transport.

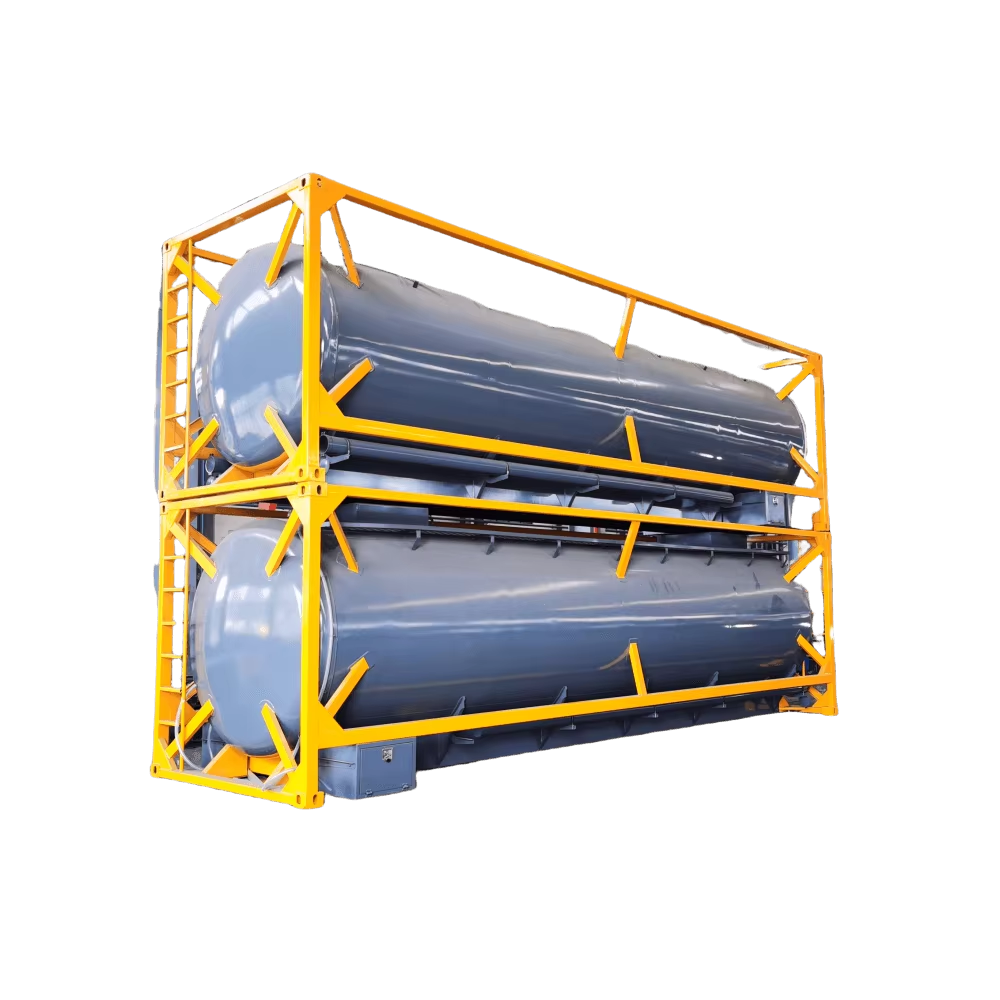

Classification of Tank Container Types by Design and Operational Use

Tank containers are categorized by specialized design:

- Pressurized tanks: Designed for liquefied gases like propane, with capacities up to 26,000 liters

- Insulated tanks: Maintain temperatures from -196°C to +80°C for cryogenic or heat-sensitive liquids

- Food-grade tanks: Feature polished stainless steel interiors and CIP (Clean-in-Place) systems for hygienic transport

These designs align with ISO 6346 standards for compatibility across rail, ship, and truck networks.

Key Applications Across Oil & Gas, Chemicals, Food & Beverages, and Pharmaceuticals

The chemical industry has seen remarkable improvements thanks to ISO tanks which slash cross contamination risks down to just 11% during acid and solvent transport according to Chemical Logistics Review from last year. When it comes to moving milk powder around, most operations now depend on specialized tanks filled with nitrogen gas to keep things fresh, something that happens in about seven out of ten cases across the dairy sector. Pharma firms have taken this even further with their insulated shipping containers equipped with smart temperature sensors throughout the supply chain. These innovations help maintain vaccine quality at an impressive rate of nearly 99.5%. And for those tricky loads like liquefied natural gas or other dangerous substances, modern vapor recovery tech speeds up the loading process significantly, cutting time spent on site roughly in half compared to older methods.

Specialized Uses in Food-Grade and Pharmaceutical Shipping

Maintaining Purity: Food-Grade Tank Containers for Dairy and Beverage Logistics

Tank containers designed for food transport must adhere to very high hygiene requirements when carrying things like dairy products and drinks. These tanks are typically made from stainless steel that won't corrode easily. The cleaning process is pretty intense too, with most facilities getting their sanitation practices checked regularly by outside experts. Around 98% of companies have switched to automated cleaning systems these days, which helps prevent any mix-up between different products according to recent compliance reports. For items that need extra protection, manufacturers often install special aseptic liners inside the tanks and sometimes flush them with nitrogen gas. This keeps everything fresh during transport, especially important for delicate stuff like concentrated fruit juices and milk that's been heated to ultra high temperatures for preservation.

Temperature-Controlled and Insulated Tank Solutions for Pharmaceutical Transport

Specialized tanks used in pharmaceutical transport offer tight temperature control ranging from -70 degrees Celsius all the way up to +50 degrees, plus they come equipped with internet-connected sensors that track conditions during shipping of sensitive products like vaccines and biological drugs. Market analysts expect this sector to expand quite rapidly, around 7.8 percent each year until 2030 mainly because of how much mRNA vaccines need to be kept cool during transportation worldwide. Some cutting edge models feature double layer vacuum insulation combined with special materials that change state when heated or cooled, allowing these containers to keep things stable thermally for well over two weeks even if there's no electricity supply available somewhere along the route. This kind of reliability helps avoid massive financial losses estimated at nearly five billion dollars every year according to recent World Health Organization reports on cold chain management. Plus, modern systems include GPS devices that show exactly where shipments are at any given moment, together with digital records maintained through blockchain technology which makes sure everything follows proper guidelines set forth by Good Distribution Practices standards.

Smart Technology and IoT Integration in Modern Tank Container Systems

Real-Time Monitoring with Smart Sensors and Telematics

Sensors connected to the Internet of Things provide live information about temperatures accurate within half a degree Celsius, pressures reaching as high as thirty bar, and how full storage tanks are getting. According to research published by Market Research Intellect last year, putting telemetry systems inside vehicles cuts down spoilage of chemicals during transport by around two thirds because drivers get warnings right away when something goes wrong. Containers fitted with GPS technology actually know when they're near dangerous areas and will change course automatically, which makes handling dangerous goods much safer overall for everyone involved.

Enhancing Safety and Compliance Through Digital Tracking

The automated compliance logs track around 57 different safety factors for each shipment, from regular valve checks to confirmation that cleaning procedures were properly followed. These digital replicas can run through all sorts of stressful situations like unexpected temperature changes, helping spot possible problems long before anything actually goes wrong. Industry research shows carriers who switch to smart tank containers with internet connectivity experience about 40% fewer safety issues compared to traditional methods. That's a pretty big difference when we're talking about transporting hazardous materials across borders every day.

Predictive Maintenance and Automation in Loading and Unloading Processes

Machine learning algorithms analyze sensor data to predict maintenance needs with 92% accuracy, reducing unplanned downtime by 34% (PR Newswire 2024). Robotic arms equipped with weight sensors automate loading, optimizing distribution while adhering to ISO 1496-3 standards. These systems self-adjust flow rates based on viscosity, ensuring ±1% volume precision critical for food-grade liquids.

Sustainable Innovations in Tank Container Materials and Design

Advanced Corrosion-Resistant and Composite Materials for Longer Lifespan

Tank containers today are getting upgraded with special steel composites layered with polymers and some models even include titanium reinforcement to fight off chemical corrosion problems. According to research published last year, tanks built with these new materials had about 72 percent fewer leaks when transporting sulfuric acid than traditional carbon steel containers did. Manufacturers now commonly use automated ultrasonic tests to check for weaknesses while building these units. This quality control step helps extend their lifespan to around 25 to maybe 30 years. Such improvements definitely matter for companies dealing with dangerous substances since they need reliable containment solutions for long hauls across different environments.

Eco-Friendly Designs and Green Manufacturing Practices in Tank Production

The industry is adopting closed-loop manufacturing, with 38% of new containers incorporating recycled stainless steel. Solar-powered welding stations and water-based powder coatings reduce production emissions by up to 45%. A 2023 logistics analysis found that ISO-compliant eco-designs improve aerodynamics, cutting fuel consumption by 12% during intermodal transport.

Balancing Cost, Durability, and Environmental Responsibility in Tank Container Manufacturing

| Consideration | Traditional Approach | Sustainable Innovation | Impact |

|---|---|---|---|

| Material Selection | Single-grade steel | Multi-layer composites | 40% cost reduction over lifespan |

| Coating Systems | Solvent-based paints | Ceramic nanocoatings | 68% fewer VOC emissions |

| End-of-Life Recycling | 55-60% material recovery | 92% closed-loop recycling | $740/ton carbon offset potential |

Lifecycle assessments now guide design decisions, with hybrid aluminum-stainless steel frames offering optimal balance between durability (35+ years) and recyclability (98% recovery rate). Manufacturers adopting this approach report 19% higher ROI over a 10-year period compared to conventional models.

FAQ Section

What are tank containers used for? Tank containers are used for transporting liquid and gaseous goods efficiently across modes like rail, ship, and truck.

How do tank containers ensure safety? They are equipped with safety features such as pressure relief valves and secondary containment systems that comply with international regulations.

Why are tank containers environmentally friendly? Modern tank containers incorporate sustainable materials and design practices to reduce emissions and improve fuel efficiency.

What industries benefit from tank container logistics? Industries like oil & gas, chemicals, pharmaceuticals, and food & beverages benefit from the efficient transport solutions offered by tank containers.

Table of Contents

- The Evolution and Global Impact of Tank Containers in Liquid and Gas Logistics

- Types, ISO Standards, and Industry-Specific Applications of Tank Containers

- Specialized Uses in Food-Grade and Pharmaceutical Shipping

- Smart Technology and IoT Integration in Modern Tank Container Systems

- Sustainable Innovations in Tank Container Materials and Design